TiAl合金具有低密度、高比刚、高比强、优异的抗氧化及高温蠕变性能等优点,在航空航天领域极具应用前景,可在600~800 ℃范围内替代镍基高温合金用于制造航空发动机的热端部件,在大幅减重的同时提高发动机的热机效率[1-3]。由于Ti-48Al-2Cr-2Nb(at.%)合金在GEnx发动机低压涡轮叶片上的使用,发动机减重近400磅,燃油消耗减少20%,NOx排放量降低80%[4-5]。此外,在高端汽车制造领域,TiAl合金制造的涡轮增压器叶轮和排气阀等部件已获得商业化应用。然而,由于该类合金低的室温塑性、损伤容限及加工性能导致其零部件制造成本增加,限制了该类合金的广泛应用[6-7]。研究表明,获得均匀细小的显微组织是改善TiAl合金室温塑性的重要手段[8-10]。

目前,适用于TiAl合金晶粒细化的方法可以归为以下几类:①添加B、C、Y等元素[9-12],在合金中形成TiB、TiC、Y2O3等细化剂,可作为异质核心促进形核,并阻碍晶粒长大,从而细化晶粒;②热机械处理[13-14],主要通过锻造、扭转、挤压、轧制等高温变形方法使合金组织发生变形及再结晶等,从而在合金中获得细小的显微组织;③TiAl合金成分设计,其本质是改变合金的凝固路径,使TiAl合金经历β→α相变,形成多种α相变体,从而细化TiAl合金的显微组织[15-16];④亚稳组织分解[17],高温淬火获得亚稳组织,在回火过程中通过亚稳组织的分解细化TiAl合金显微组织。相比于其他3种方法,亚稳组织分解的方法可通过热处理实现,具有操作简单、成本低、组织调控范围大等优点。根据TiAl合金的发展历程,本文分别对传统包晶凝固TiAl合金及β型γ-TiAl合金的亚稳相形成及分解进行了综述,重点关注了热处理过程中亚稳组织分解与晶粒尺寸的相关性。

1 传统包晶凝固TiAl合金

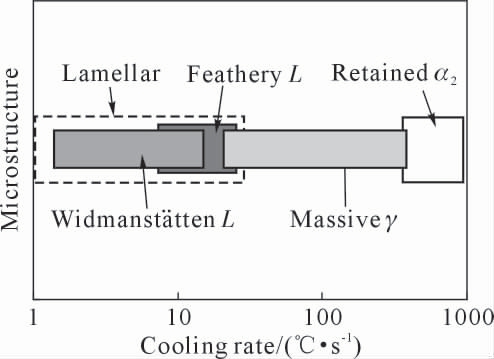

传统包晶凝固TiAl合金的相变路径为:L→L+α→α→α2+γ,在该类合金中只存在高温α单相区,因此亚稳组织均由α单相区快冷得到。当TiAl合金从α单相区冷却时,随着冷速的变化,α相的分解方式差异显著,形成不同的显微组织。图1为Ti-46Al-8Nb合金显微组织与冷却速率之间的关系,从中可以看出,随着冷却速度的增大,该合金中依次会得到片层组织γL(Lamellar structure)、魏氏组织γW(Widmansta¨tten structure)、羽毛状组织γF(Feathery structure)、块状组织γM(Massive structure)以及过冷的块状α2相。

图1 Ti-46Al-8Nb 合金显微组织与冷却速率之间的关系[18]

Fig.1 Correlation between microstructure and cooling rates of Ti-46Al-8Nb alloys[18]

当冷却速度较低时(炉冷),高温α相会经历α→α2+γ固态相变形成(α2+γ)片层结构,随着冷速的增加片层宽度会逐渐减小。在中等冷速下(空冷),(α2+γ)片层结构间会形成亚稳的魏氏板条组织γW,通常魏氏组织由具有平行关系的α2/γ片层构成,并且与周围的片层团有一定的位向关系[19-20]。Dey等[20]研究了Ti-46.8Al-1.7Cr-1.8Nb合金中α相在空冷条件下的分解行为,发现在片层团中形成了魏氏γW板条组织,γW与相邻片层团的<1-100>α2方向存在约65°取向差。随着冷却速度进一步增加(水冷),在片层团界面及片层团内部会形成羽毛状γF组织,并且γF与片层组织之间有一定的位向关系[21-22]。羽毛状γF组织由片层团中的板条组成,与周围的片层团不完全平行,两者之间存在小的取向差。Dey等[22]从Ti-46.8Al-1.7Cr-1.8Nb合金的α单相区连续快冷后,发现了两种类型的羽毛状γF组织:一部分羽毛状γF组织在片层团内部析出,并沿着片层结构的<100>γL轴方向偏转约36°±5°;另一部分γF组织在片层团边界析出,且其内部的α2/γ板条存在5°~15°的错配度。从α单相区以极快速度冷却时(冰水淬火)会发生α→γM块状转变,从而形成块状γM相。α→γM转变受短程扩散控制,不规则形状的γM相在α2/α2界面处形核,与一侧α2相符合Blackburn位向关系(<11-20>α2//<011>γ及(0001)α2//{111}γ),且朝着另一侧无Blackburn位向关系的过冷α2相生长,从而导致形成的γM相之间的界面往往不连续。Zhang等[23-24]通过在Ti-48Al-3Nb-0.5Ta合金的α单相区,快速淬火后获得了极细的块状γM相,并研究了块状α→γM相变,发现提高淬火温度会抑制γM相的形成,γM相不仅可以在α晶界处形核,还可以在α晶粒内部的缺陷处形核,与α相之间符合Blackburn位向关系。

由于亚稳组织魏氏体γW相、羽毛状γF相及块状γM相形成于非平衡相变过程,从热力学角度而言是不稳定的,极易分解。在回火过程中,α相会在γF及γM的{111}γ面上析出,由于γ相有4个等价的{111}γ面,因此会形成4种不同取向的α相。同时这些亚稳相内部含有大量的晶格缺陷,在回火过程中为α相的析出提供了更多形核位置,从而起到了细化晶粒的作用[25-27]。

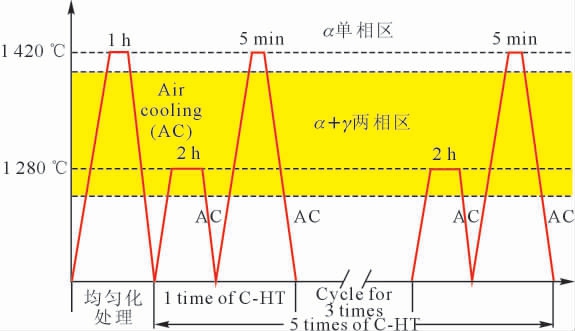

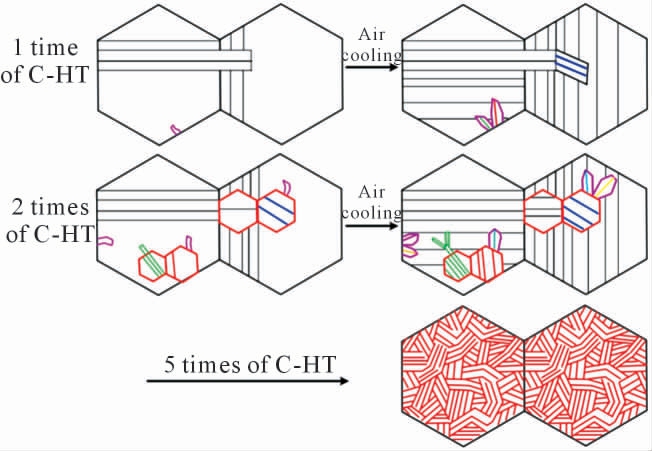

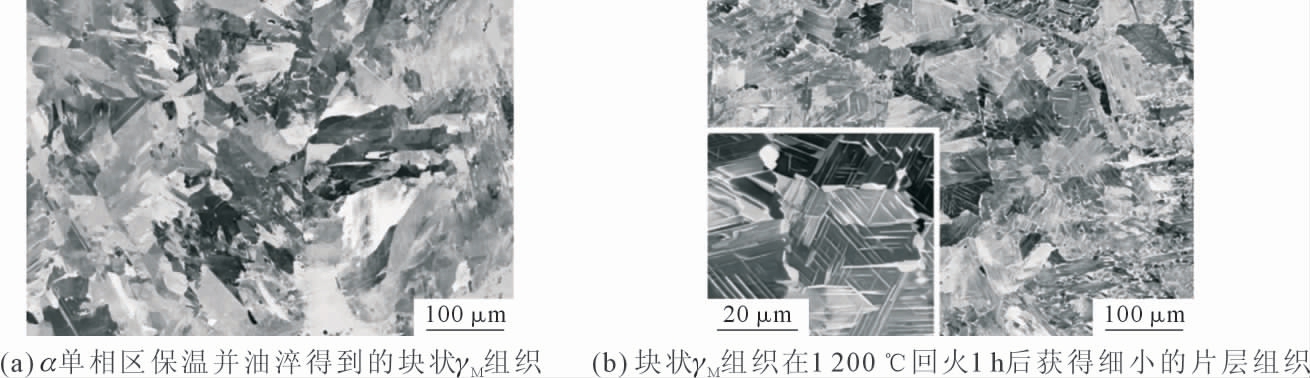

Zhang等[28-29]通过添加Ta元素促进了Ti-48Al-3Nb-1Ta合金中亚稳γW相及γF相的析出,并通过随后的循环加热,形成与初始片层团取向不同的新α晶粒,从而在空冷后形成了细小的片层团,其循环热处理工艺及相应的组织演化过程分别如图2和图3所示。Wang 等[30]研究了亚稳γF相的转变,将Ti-46Al-2Cr-2Nb合金中的γF相在(α+γ)两相区循环热处理后,羽毛状γF相的长径比明显减小,呈现柱状形貌,并在两相区长时间保温后,γF相逐渐消失,转变为10~20 μm的细小全片层结构。Clemens等[31]和Zhang等[32]利用块状γM中α相析出的细化机制,在Ti-46Al-9Nb 和Ti-48Al-2W-0.5Si合金中获得了尺寸为10~30 μm的细小片层团,如图4所示。相比于γW相及γF相,块状γM相内部含有大量的晶格缺陷,分解时形核率高,晶粒细化效果更为显著。

图2 Ti-48Al-3Nb-1Ta 合金循环空冷热处理工艺图[28]

Fig.2 Schematic of the cyclic air-cooling heat treatment route of Ti-48Al-3Nb-1Ta alloy[28]

图3 Ti-48Al-3Nb-1Ta 合金循环空冷热处理循环细化过程[29]

Fig.3 The refinement process by cyclic air-cooling heat treatment of Ti-48Al-3Nb-1Ta alloy[29]

图4 Ti-46Al-9Nb 合金在α 单相区快冷及经快冷+回火处理后的显微组织[31]

Fig.4 Microstructure of fast-cooling in a single α phase region and after fast-cooling+tempering in Ti-46Al-9Nb alloys[31]

此外,由块状转变衍生出的循环热处理也被广泛研究,通过对TiAl合金进行循环往复的加热和冷却,反复利用其中的相变过程,使晶粒同时发生形核和生长。通过工艺参数的调整,例如时效温度、保温时间、冷却速率等控制相含量及晶粒尺寸,从而达到细化合金组织的目的。Clemens等[31]对Ti-46Al-2Cr-2Mo-0.25Si-0.3B合金(Tα=1 305 ℃)进行了多步循环热处理,将该合金在1 320 ℃与1 200 ℃之间进行了3次循环热处理,片层团尺寸由120 μm减小至65 μm,片层间距为30 nm。

2 β型γ-TiAl合金

随着TiAl合金的发展,研究者们通过加入Nb、Cr、V、Mo、Mn等β相稳定化元素开发出了β型γ-TiAl合金。相比于包晶凝固TiAl合金,β型γ-TiAl合金具有凝固织构弱、组织均匀细小、热加工性能优异、服役温度高等特点。同时,由于β相稳定化元素的添加,在β型γ-TiAl合金中存在β单相区,其凝固路径为L→L+β→β→β+α→α→α2+γ。因此,β型γ-TiAl合金快冷时会形成不同的亚稳组织。与包晶凝固TiAl合金相似,β型γ-TiAl合金由α单相区快冷时可得到亚稳的γW、γF、γM组织;由β单相区快冷时会形成块状αM、马氏体α′及全B2等亚稳组织。本节着重介绍β型γ-TiAl合金在β单相区快冷过程中亚稳组织的形成与分解。

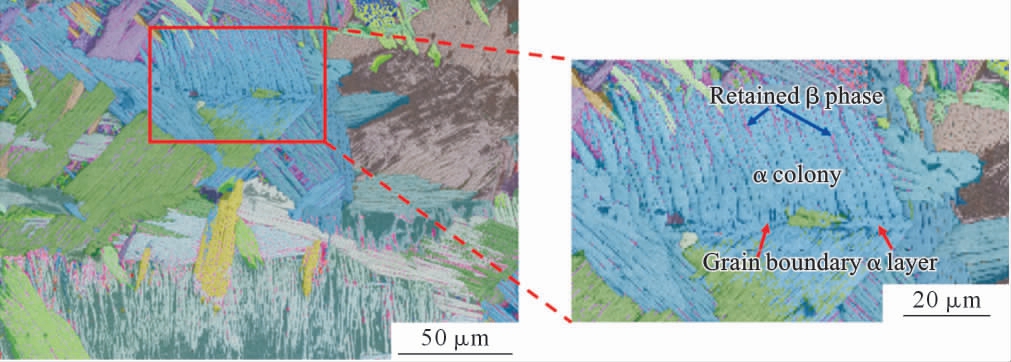

β型γ-TiAl合金由β单相区冷却时会发生不同类型的β→α转变:①在较慢的冷却速度下发生β→αW魏氏体转变(Widmansta¨tten transformation),α相在β晶界上形核并向晶内生长,与母相遵循Burgers位向关系(<11-20>α2//<1-11>B2及(0001)α2//{110}B2),成分与母相显著不同;②以中等速率冷却时发生β→αM块状转变,形成亚稳的块状αM相,αM相在β晶界处形核,生长过程无明显的长程扩散,αM与母相β之间不存在位向关系[33];③随着冷速的进一步提高,发生β→α′马氏体转变,六方晶系的α′马氏体在晶内以切变的形式析出,与母相β遵循Burgers位向关系[34-36]。Tian等[37]在Ti-40Al-8Nb 合金中观察到大量魏氏体(α colony),如图5所示,平行的魏氏体板条来源于晶界处的α相,其几乎充满β相。Appel等[38]总结了β→αW转变时魏氏体板条析出的形貌及晶体学关系:αW魏氏体的宽度平行于{11 11 13}β,长度沿着<335>β方向生长。而块状αM和马氏体α′相是亚稳态的,在回火过程中会发生分解。

图5 Ti-40Al-8Nb 合金中的魏氏体板条[37]

Fig.5 Widmansta¨tten plates in Ti-40Al-8Nb alloys[37]

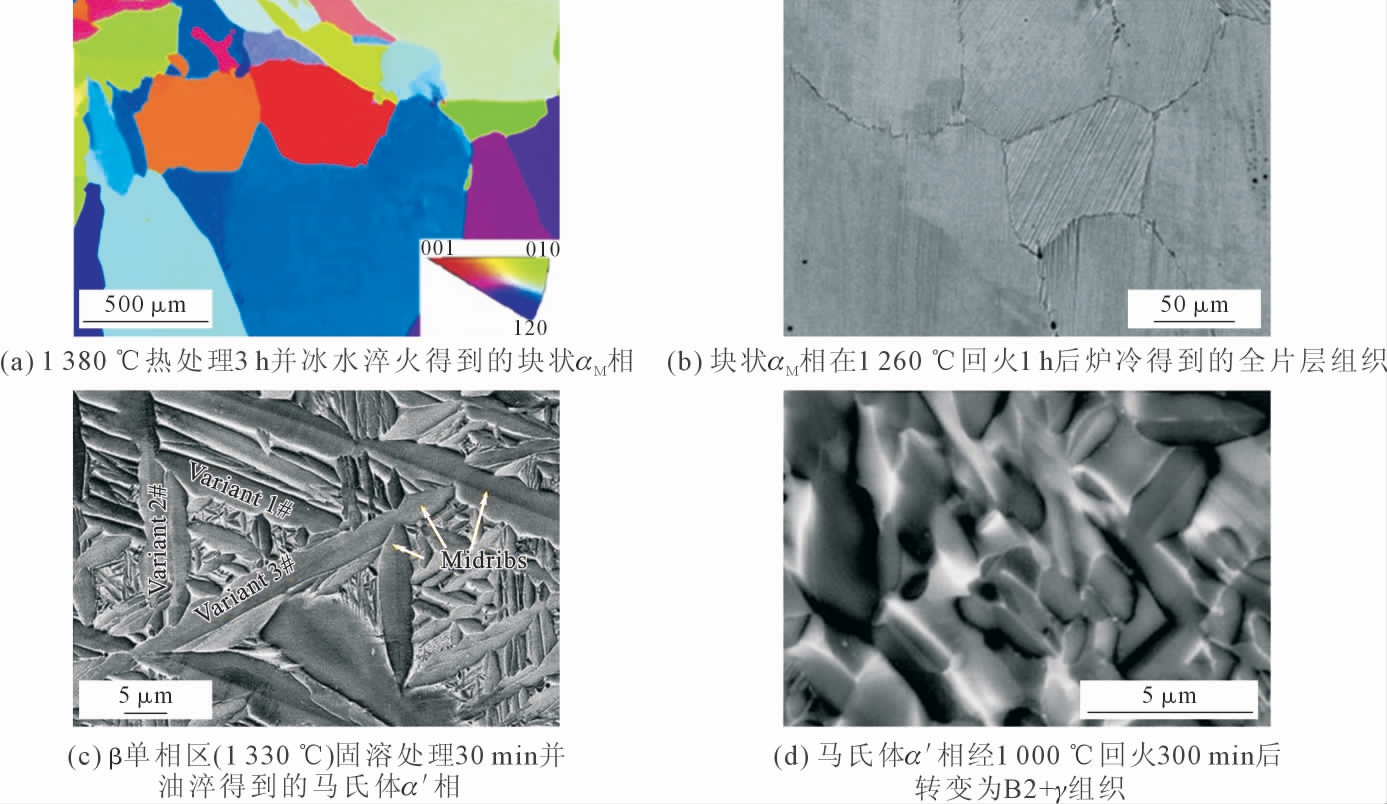

亚稳态的块状αM相及马氏体α′相在回火过程中会发生分解,时效后可形成细小的(α2+γ)全片层组织或B2+γ组织,如图6所示[35,39]。Chen等[35]在Ti-42.5Al-6Nb-1V合金中观察大量块状αM相,回火后其转变为全片层组织,如图6(a~b)所示。Cheng等[39]在Ti-42Al-8.5V合金中通过β→α′马氏体转变获得了马氏体α2′组织,在1 000 ℃回火过程中,该马氏体α2′相通过α2′→α2+γ→B2+γ相变分解为等轴的B2+γ组织,如图6(c~d)所示。

图6 Ti-42.5Al-6Nb-1V 合金中的块状αM相及全片层组织和Ti-42Al-8.5V 合金中的马氏体α′相及B2+γ 组织[35,39]

Fig.6 Massive αM and full lamellar structure inTi-42.5Al-6Nb-1V alloys,martensite α′ and B2+γ microstructure in Ti-42Al-8.5V alloys[35,39]

即使大量β稳定化元素的添加提高了β型γ-TiAl合金中β相的稳定性,但在极高的冷速下也难以将高温β相保留至室温形成过冷度更大的亚稳全B2相。为了获得亚稳全B2相,Mayer等[40-41]通过添加极强的β稳定化元素Mo,在Ti-44Al-7Mo合金的β单相区固溶处理并水淬后,观察到了亚稳全B2相。Yang等[42-43]通过合金成分设计,通过减少Al含量扩大β单相区温度范围,并添加大量β稳定化元素Nb,在Ti-40Al-8Nb合金的β单相区淬火后获得了亚稳全B2相。

由TiAl合金的相变序列可知,温度由高到低依次出现的固相为β相、α相及γ相,通过高温淬火可获得相应的亚稳组织,因此在上述亚稳相中,亚稳全B2相所含过冷度更大,分解时驱动力大幅增加,析出相形核率高,在回火过程中会形成更均匀细小的显微组织。Erdely等[44]将亚稳全B2相在1 000 ℃保温后,从中析出了亚微米γ相,形成了(B2+γ)组织,将合金显微组织细化至约500 nm。Yang等[42-43]表明亚稳全B2相的分解受合金元素及时效温度的影响显著,由于Nb元素的添加促进了ω0相的形成,因此在800 ℃回火时,亚稳全B2相转变为亚微米(ω0+γ)组织。改变回火温度后,在1 000 ℃保温过程中,亚稳全B2相分解为平均晶粒尺寸约2 μm的等轴(α2+γ)组织,见图7。

图7 Ti-40Al-8Nb 合金中铸态组织、亚稳全B2 相及超细晶组织[42-43]

Fig.7 As-cast microstructure,metastable fully-B2 phase and ultra-refined microstructure in Ti-40Al-8Nb alloys[42-43]

3 组织细化对合金性能的影响

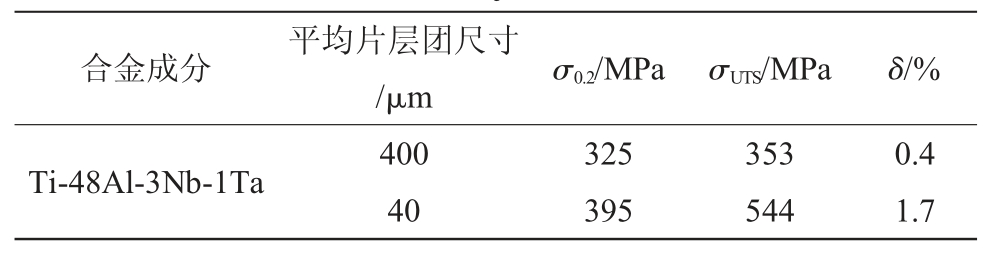

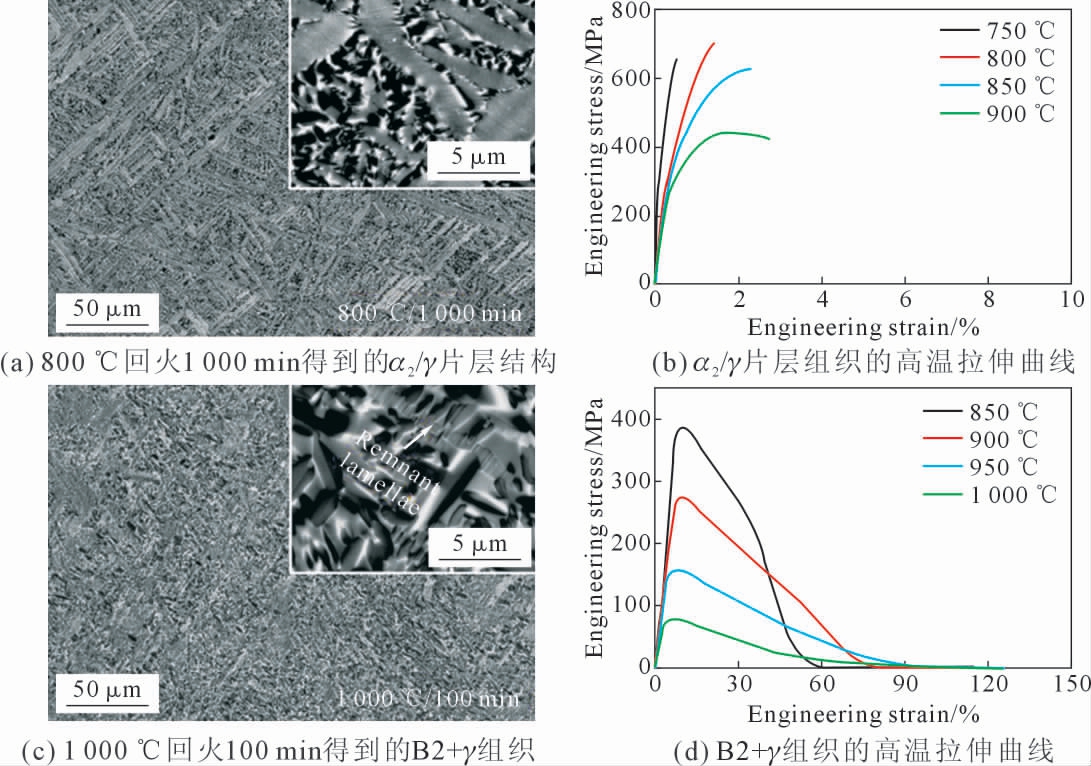

细小的显微组织会改善TiAl合金的室温塑性,并且随着晶粒尺寸的减小TiAl合金的热加工性能显著提升,因此TiAl合金组织细化对合金力学性能的影响也受到极大关注。张可人[29]对Ti-48Al-3Nb-1Ta合金经过循环空冷热处理之前粗片层团组织(~400 μm)和循环空冷热处理之后细片层团组织(~40 μm)进行了室温拉伸实验,表明随着TiAl合金片层团尺寸的减小,其室温拉伸强度与塑性都得到提高,见表1。Cheng等[39]比较了Ti-42Al-8.5V合金中近片层α2/γ结构与细小的等轴(B2+γ) 组织的高温拉伸性能,见图8。结果表明均匀细小的等轴晶组织表现出良好的热加工性能甚至超塑性,更适合二次加工。

表1 TiAl合金的室温拉伸性能[29]

Table 1 Room temperature tensile properties of TiAl alloys[29]

合金成分 平均片层团尺寸/μm σ0.2/MPa σUTS/MPa δ/%Ti-48Al-3Nb-1Ta 400 325 353 0.4 40 395 544 1.7

图8 Ti-42Al-8.5V 合金中的α2/γ 片层和B2+γ 组织及高温性能[39]

Fig.8 Microstructure and high temperature properties of α2/γ lamellar structure and B2+γ of Ti-42Al-8.5V alloys[39]

4 结语

综上所述,通过TiAl合金在热处理过程中亚稳组织的转变可有效细化合金的显微组织,其本质是高温淬火获得亚稳组织,在回火过程中通过亚稳组织的分解细化合金晶粒尺寸,亚稳组织过冷度越大,析出相形核率越高,晶粒细化效果更为显著。然而,由于TiAl合金的本征脆性及较大的淬火应力会导致合金发生严重的开裂现象,是淬火-回火方法细化组织必须解决的问题。因此,在后续研究中可以考虑通过合金成分设计提高合金淬透性或优化淬火介质,避免合金在快冷过程中引起的开裂。

[1]杨锐.钛铝金属间化合物的进展与挑战[J].金属学报,2015,51(2):129-147.

[2]林均品,陈国良.TiAl基金属间化合物的发展[J].中国材料进展,2009,28(1):31-37.

[3]SONG L, APPEL F, WANG L, et al.New insights into high-temperature deformation and phase transformation mechanisms of lamellar structures in high Nb-containing TiAl alloys[J].Acta Materialia,2020,186:575-586.

[4]KIM Y W, KIM S L.Advances in gammalloy materials-processes-app lication technology: Successes, dilemmas, and future[J].JOM,2018,70(4):553-560.

[5]APPEL F, CLEMENS H, FISCHER F D.Modeling concepts for intermetallic titanium aluminides[J].Progress in Materials Science,2016,81:55-124.

[6]IMAYEV R M,IMAYEV V M,OEHRING M,et al.Alloy design concepts for refined gamma titanium aluminide based alloys[J].Intermetallics,2007,15(4):451-460.

[7]KOTHARI K, RADHAKRISHNAN R, WERELEY N M.Advances in gamma titanium aluminides and their manufacturing techniques[J].Progress in Aerospace Sciences,2012,55:1-16.

[8]WEI D X, KOIZUMI Y, NAGASAKO M, et al.Refinement of lamellar structures in Ti-Al alloy[J].Acta Materialia, 2017, 125:81-97.

[9]TIAN P J,YANG G,GE Z H,et al.Microstructural refinement of a Ti-40Al-8Nb-0.5B alloy by hot deformation within (α+β) phase field and subsequent tempering[J].Advanced Engineering Materials,2019,21(8):1900239.

[10]TAN Y M, CHEN R R, FANG H Z, et al.Enhanced strength and ductility in Ti46Al4Nb1Mo alloys via boron addition[J].Journal of Materials Science&Technology,2022,102:16-23.

[11]LI M G,XIAO S L,CHEN Y Y,et al.The effect of carbon addition on the high-temperature properties of β solidification TiAl alloys[J].Journal of Alloys and Compounds,2019,775:441-448.

[12]GU X,JIANG S D,CAO F Y,et al.A β-solidifying TiAl alloy reinforced with ultra-fine Y-rich precipitates[J].Scripta Materialia,2021,192:55-60.

[13]TANG B,CHENG L,KOU H C,et al.Hot forging design and microstructure evolution of a high Nb containing TiAl alloy[J].Intermetallics,2015,58:7-14.

[14]ZHANG S Z,ZHANG C J,DU Z X,et al.Deformation behavior of high Nb containing TiAl based alloy in α+γ two phase field region[J].Materials&Design,2016,90:225-229.

[15]YANG J R, WANG X Y, CAO B, et al.Tailoring the microstructure of a β-solidifying TiAl alloy by controlled post-solidification isothermal holding and cooling[J].Metallurgical Materials Transactions A,2017,48(10):5095-5105.

[16]YANG G,KOU H C,YANG J R,et al.In-situ investigation on the β to α phase transformation in Ti-45Al-8.5Nb-(W,B,Y)alloy[J].Journal of Alloys and Compounds,2016,663:594-600.

[17]FANG H Z, CHEN R R, ANTON G, et al.Effect of cyclic heat treatment on microstructures and mechanical properties of directionally solidified Ti-46Al-6Nb alloy[J].Transactions of Nonferrous Metals Society of China,2015,25(6):1872-1880.

[18]HU D,HUANG A,GREGOIRE A,et al.The 3rd international conference on advanced materials processing:Determining continuous cooling phase transformation behaviour in Ti-46Al-8Nb using Jominy end quenching[C]//Melbourne: Institute of Materials Engineering Australasia Ltd.,2004.

[19]HUD,HUANGAJ,WUX.TEM characterisation of widmansta¨tten microstructures in TiAl-based alloys[J].Intermetallics, 2005, 13(2):211-216.

[20]DEY S R, HAZOTTE A, BOUZY E, et al.Development of widmansta¨tten laths in a near-γ TiAl alloy[J].Acta Materialia, 2005,53(14):3783-3794.

[21]LIU Y,HU R,KOU H C,et al.A mixture of massive and feathery microstructures of Ti48Al2Cr2Nb alloy by high undercooled solidification[J].Materials Characterization,2015,100:104-107.

[22]DEY S R, BOUZY E, HAZOTTE A.Features of feathery γ structure in a near-γ TiAl alloy[J].Acta Materialia, 2008, 56(9):2051-2062.

[23]ZHANG K R,HU R,LEI T C,et al.Refinement of massive γ phase with enhanced properties in a Ta containing γ-TiAl-based alloys[J].Scripta Materialia,2019,172:113-118.

[24]ZHANG K R, HU R, YANG J R, et al.The phase transformation behavior between γ lamellae and massive γ in a Ta containing TiAl-based alloy[J].Journal of Alloys and Compounds,2020,821:153290.

[25]ZHANG W J, EVANGELISTA E, FRANCESCONI L.Effect of prior cooling rate on the grain size of fully-lamellar TiAl-base alloy developed by tempering/quenching[J].Scripta Materialia,1996,35(1):41-45.

[26]ZHANG W J, FRANCESCONI L, EVANGELISTA E.A novel heat treatment to develop very fine lamellar structure in cast gamma-base TiAl alloys[J].Materials Letters,1996,27(4):135-138.

[27]ZHANG W J,EVANGELISTA E,FRANCESCONI L.Microstructural variation of a cast Ti48Al2W0.5Si alloy during quenching and tempering [J].Materials Science and Engineering: A,1996, 220(1-2):15-25.

[28]ZHANG K R, HU R, LI J G, et al.Grain refinement of 1 at.%Ta-containing cast TiAl-based alloy by cyclic air-cooling heat treatment[J].Materials Letters,2020,274:127940.

[29]张可人.含Ta过包晶TiAl合金凝固组织与亚稳结构的演变机制[D].西安:西北工业大学,2020.

[30]WANG J N,YANG J,XIA Q F,et al.On the grain size refinement of TiAl alloys by cyclic heat treatment[J].Materials Science and Engineering:A,2002,329-331:118-123.

[31]CLEMENS H, BARTELS A, BYSTRZANOWSKI S, et al.Grain refinement in γ-TiAl-based alloys by solid state phase transforma-tions[J].Intermetallics,2006,14(12):1380-1385.

[32]ZHANG W J, CHEN G L, EVANGELISTA E.Formation of α phase in the massive and feathery γ-TiAl alloys during aging in the single αfield[J].Metallurgical and Materials Transactions A,1999,30:2591-2598.

[33]AHMED T, RACK H J.Phase transformations during cooling in α+β titanium alloys[J].Materials Science and Engineering: A,1998,243(1):206-211.

[34]MAYER S,PETERSMANN M,FISCHER F D,et al.Experimental and theoretical evidence of displacive martensite in an intermetallic Mo-containing γ-TiAl based alloy[J].Acta Materialia, 2016,115:242-249.

[35]CHEN L, LIN J P, XU X J, et al.Microstructure refinement via martensitic transformation in TiAl alloys[J].Journal of Alloys and Compounds,2018,741:1175-1182.

[36]CHEN L,LIN J P,XU X J,et al.Microstructural evolution and refinement of as-forged Ti-43Al-9V-Y alloy after quenching and tempering[J].Intermetallics,2019,113:106576.

[37]TIAN P J, YANG G, GE Z H, et al.Responses of microstructure and texture of α phase to boron addition in Ti-40Al-8Nb-xB alloys modified by hot deformation above the β transus[J].Materials Characterization,2019,153:148-156.

[38]APPEL F,PAUL D H, OEHRING M.Gamma titanium aluminide alloys: science and technology[M].Berlin: Wiley-VCH Verlag GmbH&Co.KGaA,2011.

[39]CHENG L,ZHANG S J,YANG G,et al.Tailoring microstructure and mechanical performance of a β-solidifying TiAl alloy via martensitic transformation [J].Materials Characterization, 2021,173:110970.

[40]MAYER S,SAILER C,SCHMOELZER T,et al.On phase equilibria and phase transformations in β/γ-TiAl alloys-a short review[J].BHM Berg-und Hüttenma¨nnische Monatshefte, 2011, 156(11):438-442.

[41]SCHMOELZER T,MAYER S,SAILER C,et al.In situ diffraction experiments for the investigation of phase fractions and ordering temperatures in Ti-44 at% Al-(3-7) at% Mo alloys[J].Advanced Engineering Materials,2011,13(4):306-311.

[42]YANG G,YANG X X,WANG Y F, et al.Phase precipitation behavior of a quenched β-solidifying TiAl alloy with a fully-B2 microstructure during annealing at 800 ℃[J].Journal of Alloys and Compounds,2020,812:152118.

[43]YANG G,YANG X X,KOU H C,et al.Microstructure refinement of Ti-40Al-8Nb alloys via the decomposition of the metastable B2 phase at 1 000 ℃[J].Journal of Alloys and Compounds, 2020,838:155575.

[44]ERDELY P,STARON P,STARK A,et al.In situ and atomic-scale investigations of the early stages of γ precipitate growth in a supersaturated intermetallic Ti-44Al-7Mo(at.%) solid solution[J].Acta Materialia,2019,164:110-121.